Located in Yame City, southern Fukuoka Prefecture, the second largest city in the region by area, lies a concentration of Japanese culture, tradition, and craftsmanship.

Nestled in the mountains about 5 kilometers from central Yame is the “Morikou Blacksmith Workshop,” where Japan’s finest knives are crafted with masterful skill and unwavering dedication. Their exceptional sharpness has attracted many visitors.

A Lifetime Investment

The workshop resonates with the sound of metal striking metal, where refined techniques and blades shine with brilliance.

Yasunaka Taira, who inherited Morikou as its second generation, carries on the artisan spirit while expanding beyond agricultural tool manufacturing to pursue knife-making as a new challenge. His exceptional knife-making skills were acquired through apprenticeship in Osaka, the heart of blade crafting, after graduating high school.

Characteristics of Morikou Knives

The primary characteristic of Morikou knives is their “exceptional sharpness.”

They also boast top-class durability, using the highest-grade steel called “Yasuki Steel” (安来鋼). By sandwiching this steel between stainless steel layers that resist rust, they achieve both durability and cutting performance in these masterpieces.

The knives neither bend nor break, lasting for generations. While they gradually become smaller through regular sharpening, this is the secret to their decades-long usability.

The sharpness of these knives directly affects the taste of dishes, making them indispensable for Japanese chefs who require precise cutting, especially for sashimi. They are known to be “too sharp” – their only “flaw” is their exceptional sharpness.

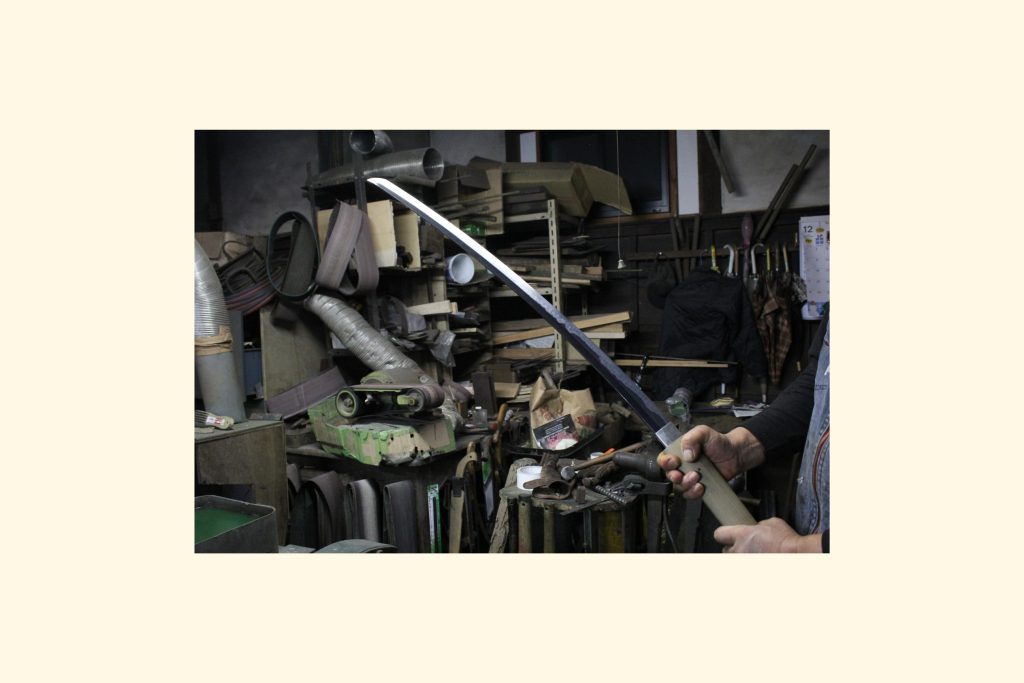

Japanese Swords

Beyond knives, the workshop also forges Japanese swords.

These swords are rooted in the tradition of the Kamakura and Heian periods, crafted with techniques passed down from the legendary swordsmiths of Setouchi, Okayama. They feature distinctive ripple patterns, a hallmark of their craftsmanship.

Taimei-san holds a Japanese sword-making license and acquired much of his expertise through independent study, including online videos, despite also training under a master swordsmith. His ability to create Japanese swords stems from the same dedication that underpins his knife-making craft—a testament to his mastery as an artisan.

What Does It Take to Become a Swordsmith?

There are only about 350 licensed swordsmiths in Japan.

Becoming one requires at least five years of apprenticeship under a certified swordsmith approved by the Agency for Cultural Affairs. The licensing exam itself includes an intensive 8-day practical test, making it an extremely rigorous qualification.

Mastery Without Compromise

As Taimei-san explains, “Even among blacksmiths, swordsmiths stand at the pinnacle. However, being a top-tier blacksmith requires the ability to skillfully adapt different types of steel to create blades with excellent sharpness.”

Unlike typical blacksmithing workshops, where production is divided among specialists, Morihiro Forging Workshop follows a fully integrated process. Each knife is painstakingly crafted with care and precision, foregoing mass production to ensure that every piece meets the highest standards.

The Morihiro Blacksmith Workshop prides itself on its high-quality craftsmanship. It is said that crafting a single blade takes about two days.

During the forging process, any overheated metal is discarded without hesitation. This uncompromising dedication is what brings out the sharpness and brilliance of their blades.

The blacksmith’s craftsmanship truly shines during the forging process.

Using a blower to create airflow, the craftsmen adjust the intensity of the fire while carefully observing the flames to determine the correct heat.

Specifically, the temperature must be controlled to reach 1350°C. This is judged by observing the flame’s color transition from orange to yellow and by noting the sparkler-like particles that appear within the flames.

When crafting swords, they use “tamahagane,” a traditional Japanese steel of extremely high purity. Through a technique called “folding and forging,” they repeat the process 13 to 15 times to further purify the steel. The charcoal used to fuel the fire is also of premium quality, ensuring it produces no sparks. Just the forging process for a sword alone can take two days.

By meticulously selecting materials and utilizing their expertise, the craftsmen spend countless hours refining the steel to a purity of less than 1%. Only then is an authentic Japanese sword completed. Indeed, Japanese swords are the epitome of the craftsman’s hard work and dedication.

At Morihiro Blacksmith Workshop, no steps in the process are rushed. While mechanization is possible, it’s difficult to produce truly excellent products this way. Handcrafted items have a unique quality that is distinctly reflected in their sharpness, explains Mr. Taihei Hira.

The dedication to creating each piece with great care stems from the pure joy of seeing satisfied customers. Imagining the moment when their work reaches the hands of someone unknown, Mr. Hira pours his uncompromising spirit into each blade. His sincere approach is vividly reflected in the brilliance of every edge he crafts.

In an era where modern civilization evolves endlessly, prioritizing convenience and efficiency, artisans dedicated solely to bringing smiles to visitors’ faces are becoming a rarity. Amid the wave of commercialization, where convenience and price dominate, the accumulated expertise of craftsmen quietly fades away.

Nevertheless, these artisans continue to uphold their beliefs and pride, preserving the vanishing light of their craft. Among these fading techniques, some continue to shine across time. True value—something that cannot be measured by convenience or efficiency—is understood and cherished by those who recognize it. As long as such people exist, the soul of the artisans will never be extinguished.

Choosing not short-term profits but decisions that look toward the future is essential. Regardless of how times change, the works created by artisans leave a deep impression on people’s hearts. This is because they carry the “thoughts” imbued through painstaking care and effort.

Thus, we must pause and reflect: What truly holds value? Preserving and passing it on to the next generation is our responsibility.

====

Morihiro Blacksmith Workshop

Address:440-4 Shiraki, Tachibana-machi, Yame City, Fukuoka Prefecture

**WEB: https://www.hocho-morihiro.com/

MAP:https://maps.app.goo.gl/eZuzWeUxVUfABTb36

Instagram: NON